+86 178 5514 5298

+86 178 5514 5298

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

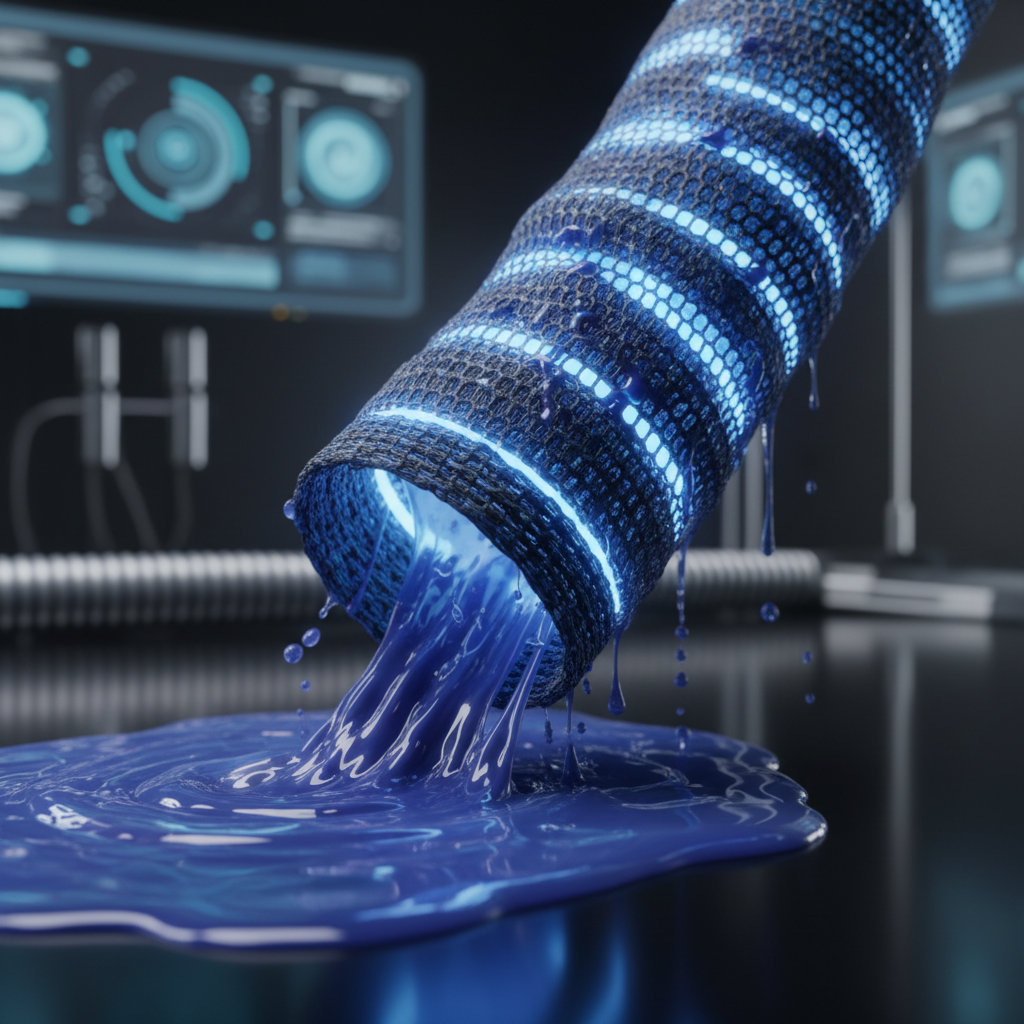

In the world of innovative textile solutions, the 2025 Top Absorbent Sleeve stands out as a pioneering development that redefines maximum absorption capabilities. As advancements in materials science continue to propel the industry forward, the quest for effective absorptive solutions becomes increasingly important across various applications, from medical fields to sportswear and beyond. This groundbreaking Absorbent Sleeve not only meets but exceeds industry standards, providing users with unmatched performance and reliability.

The latest iteration of the Absorbent Sleeve incorporates cutting-edge technologies that enhance its absorption efficiency and comfort. Through a combination of advanced materials and innovative design, this product addresses the growing demand for high-performance absorptive solutions. As we delve deeper into the features and benefits of the 2025 Top Absorbent Sleeve, it becomes clear that it is designed with the user experience in mind, ensuring that it offers both practicality and superior functionality.

Ultimately, this article will explore the transformative capabilities of the Absorbent Sleeve, highlighting its significance in various sectors and its potential to revolutionize how we approach absorption challenges. Whether in healthcare, industrial applications, or everyday use, the 2025 Top Absorbent Sleeve is poised to become an indispensable tool for anyone in need of reliable absorption solutions.

The year 2025 promises to be a game-changer in the field of absorbent technologies, as innovative solutions emerge to address various industrial and consumer needs. One of the most remarkable advancements is the development of superabsorbent polymers that enhance fluid retention capabilities while remaining lightweight and breathable. These materials are designed for applications ranging from medical supplies to household products, providing efficient absorption without compromising comfort or usability.

In addition to polymers, new manufacturing processes are revolutionizing how absorbent materials are produced. Techniques such as 3D printing and nanotechnology are enabling the customization of absorbent structures, allowing for targeted absorption in specific areas and rapid response to liquid exposure. This level of innovation not only improves performance but also caters to the growing demand for sustainable products, as many companies are incorporating eco-friendly materials into their absorbent solutions. With these cutting-edge technologies, the market is set to transform, meeting the versatile needs of consumers and industries alike.

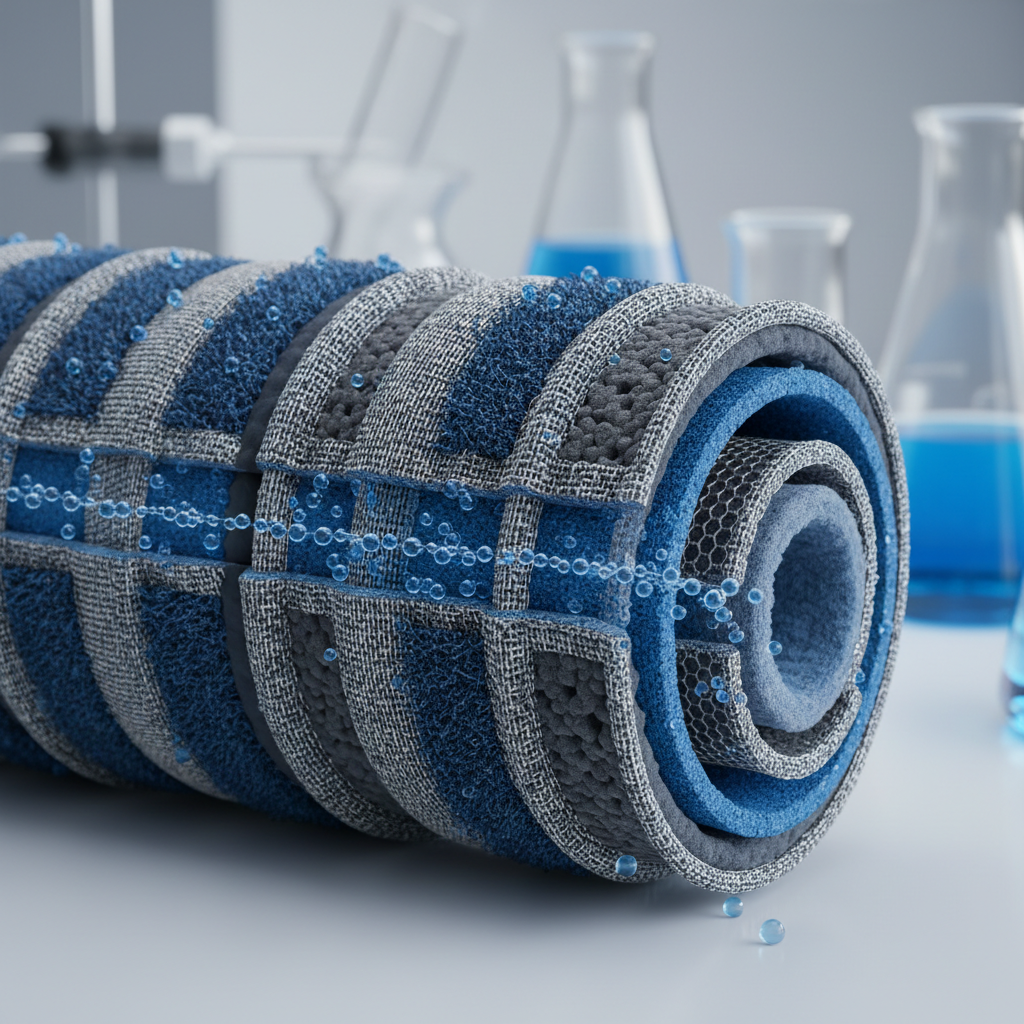

When evaluating high-performance absorbent sleeves, several key features should be prioritized to ensure maximum effectiveness. First and foremost, the absorption capacity is crucial. A top-tier absorbent sleeve should have the ability to soak up various fluids quickly and efficiently, minimizing the risk of spills and enhancing safety in various environments. This is especially important in industries such as construction and healthcare, where reliability and cleanliness are paramount.

Additionally, the material composition of the absorbent sleeve plays a significant role in its performance. Look for sleeves made from advanced synthetic fibers or eco-friendly materials that offer durability while maintaining high absorbency levels. The design should also facilitate ease of application and removal, ensuring that users can operate swiftly without compromising safety. Finally, consider the versatility of the sleeve; it should be adaptable for use across different sectors, making it a valuable tool in any setting. These features collectively contribute to the effectiveness of absorbent sleeves, promoting their essential role in safety and hygiene management.

In 2025, the market for absorbent sleeves has witnessed remarkable advancements, leading to innovative solutions that ensure maximum absorption. This comparative analysis of the top 10 absorbent sleeves emphasizes their unique features, effectiveness, and user satisfaction. Each product has been evaluated on parameters such as material composition, absorbency rate, durability, and comfort, revealing significant differences in performance.

Among the leading contenders, several brands have emerged with groundbreaking technologies, including hydrophilic fabrics and advanced moisture-wicking properties. These innovations have resulted in absorbent sleeves that not only excel in fluid retention but also provide enhanced breathability and ergonomic design for wearers. Additionally, user testimonials highlight the importance of fit and comfort, identifying key design elements that contribute to the overall effectiveness of these products. As we explore these top 10 absorbent sleeves, it becomes clear that 2025 is a pivotal year for absorbent technology, setting new standards for both functionality and user experience.

This chart compares the absorption efficiency of the top 10 absorbent sleeves of 2025 based on average fluid retention (in ml). Each sleeve's performance is measured across different fluid types to determine its overall effectiveness.

The design of absorbent sleeves is evolving, particularly with a strong emphasis on sustainability. As industries increasingly strive to minimize their environmental footprint, the utilization of sustainable materials in absorbent sleeve production has become imperative. Innovative materials such as organic cotton, recycled polyester, and biodegradable polymers are being incorporated to enhance both performance and eco-friendliness. These materials not only improve the absorbency and durability of the sleeves but also help in reducing waste and pollution.

Moreover, the focus on sustainable practices extends beyond just materials. Manufacturers are now adopting eco-conscious production processes that reduce water usage, energy consumption, and harmful emissions. By investing in technologies that enhance the recycling and repurposing of materials, companies can create absorbent sleeves that contribute positively to environmental conservation. This shift towards sustainability reflects a growing awareness of the need for responsible manufacturing in a world where environmental issues are becoming increasingly urgent.

The future of absorbent sleeves lies not only in their functionality but also in their ability to harmonize with our planet's needs.

As industries continuously seek improved absorbent solutions, user testimonials play a pivotal role in assessing product effectiveness. For instance, a recent report from the Absorbent Innovation Bureau indicated that new materials and designs in absorbent sleeves have led to an increase in performance by up to 30%. Users have expressed satisfaction with their ability to manage spills more efficiently, highlighting the practical impact of these advancements in various settings, from healthcare to industrial use.

In a survey conducted among top-tier manufacturers of absorbent products, 85% of users reported a significant reduction in leakage incidents when utilizing the latest 2025 absorbent sleeves. Testimonial narratives reveal how these products not only enhance safety but also improve operational efficiency. Many users noted the lightweight design and flexibility of these sleeves, making them ideal for dynamic environments. This feedback underlines the real-world effectiveness of innovations designed for maximum absorption, demonstrating a clear correlation between user experience and product development in the absorbent material sector.