+86 178 5514 5298

+86 178 5514 5298

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

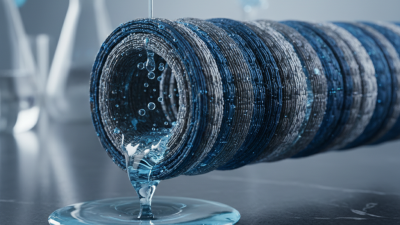

In the industrial landscape, the choice of absorbent materials is critical for maintaining safety and efficiency, particularly in environments prone to spills and leaks. The Absorbent Sleeve, a tailored solution for containing and mitigating spills, has emerged as an essential tool across various sectors, including manufacturing, healthcare, and transportation. According to a report by the International Spill Response Association, the global absorbent materials market is projected to grow significantly, reaching an estimated value of $5 billion by 2025, underscoring the increasing demand for effective and reliable spill containment solutions.

Expert insights also reinforce the importance of selecting the appropriate absorbent sleeve for specific applications. Dr. Emily Harper, a leading authority in spill management, asserts, "The right absorbent sleeve can drastically reduce cleanup time and minimize environmental impact during a spill event." This highlights the necessity for industries to evaluate their unique requirements carefully, considering factors such as liquid type, volume, and absorbency rate.

Choosing the right absorbent sleeve not only enhances workplace safety but also promotes compliance with environmental regulations. By understanding the characteristics of various absorbent sleeves, organizations can make informed decisions that optimize both performance and sustainability, ultimately leading to safer operational practices.

Absorbent sleeves play a crucial role in various industries by providing effective solutions for managing spills and maintaining cleanliness. These specialized products are designed to contain and absorb liquids, preventing spills from spreading and causing potential hazards. According to a report by the National Safety Council, about 3 million workplace injuries occur annually due to slips and falls, often exacerbated by liquid spills. Utilizing the appropriate absorbent sleeve can significantly reduce these risks, creating a safer environment in industrial settings, laboratories, and even at home.

Different applications demand specific characteristics from absorbent sleeves. In medical and healthcare environments, for instance, absorbent sleeves are essential for maintaining hygiene and safety during procedures. The Healthcare Purchasing News reported that approximately 30% of healthcare-associated infections can be traced back to improper handling of spills and waste. Thus, selecting sleeves that offer high absorption rates and are resistant to bacteria can minimize these risks. Similarly, in manufacturing sectors, sleeves designed for heavy-duty wear can withstand harsh conditions and higher volumes of liquid, ensuring that your facility remains compliant with safety regulations while enhancing operational efficiency.

When selecting the right absorbent sleeve, understanding the various types available and their specific applications is crucial. Absorbent sleeves are designed to contain liquids and prevent spills in a variety of environments. For instance, polypropylene sleeves are commonly used in industrial settings due to their chemical resistance and durability, making them ideal for containing oils and hazardous substances. According to a report by the Environmental Protection Agency, the use of properly designed absorbent products can reduce spill-related incidents by up to 30%, highlighting their importance in risk management.

Another type, made from natural cellulose fibers, is often preferred for environments requiring a more eco-friendly solution. These absorbent sleeves not only excel in absorbing water and similar liquids but are also biodegradable, making them a suitable choice for environmentally-conscious industries. A study from the International Waste Management Association indicates that utilizing biodegradable absorbents can significantly lower landfill contributions from industrial waste. Understanding these distinctions empowers users to select absorbent sleeves tailored to their specific usage needs, ensuring effectiveness and compliance with environmental standards.

| Type of Absorbent Sleeve | Material | Absorption Capacity | Best Use Cases |

|---|---|---|---|

| Polyester Sleeve | Polyester Fiber | Up to 3 liters | Oil spills, chemical containment |

| Cotton Sleeve | Cotton | Up to 2 liters | Water-based spills, general cleaning |

| Nylon Sleeve | Nylon Mesh | Up to 4 liters | Heavy-duty applications, industrial use |

| Polypropylene Sleeve | Polypropylene | Up to 5 liters | Hazardous materials, chemical spills |

| Foam Sleeve | Polyurethane Foam | Up to 6 liters | High absorption needs, damp environments |

When selecting the right absorbent sleeve for your specific needs, several critical factors must be considered to ensure optimal performance. One of the primary considerations is the material composition of the sleeve. According to a recent industry report from Global Market Insights, absorbent sleeves made from high-quality polypropylene or polymer blends exhibit superior liquid retention capabilities, making them ideal for high-absorbency applications. These materials not only effectively contain spills but also offer a heightened degree of durability, which is essential for environments subject to wear and tear.

Another significant factor is the size and compatibility of the absorbent sleeve with the equipment or area it is intended to protect. The American Society of Safety Professionals suggests that choosing an appropriately sized sleeve is crucial for preventing leaks and minimizing hazards. Oversized sleeves may fail to provide adequate coverage, while undersized options can lead to inadequate absorption. Additionally, understanding the specific liquids being dealt with—whether oil-based, water-based, or hazardous—can greatly influence the choice of absorbent sleeve, as different materials interact differently with various substances. This tailored approach enhances efficiency and safety in workplace environments and industrial applications.

When choosing an absorbent sleeve, one of the most critical factors to consider is the material used in its construction. Various materials offer distinct benefits tailored to specific needs and environments. For instance, cotton and polyester blends are popular for their balance of absorbency and durability, making them ideal for general use. Cotton is known for its exceptional absorbent properties, allowing it to soak up liquids efficiently, while polyester adds strength and resistance to wear over time.

Another option to look into is synthetic materials like polypropylene or polyethylene. These materials are often used in specialized applications due to their enhanced moisture-wicking capabilities and resistance to certain chemicals. For environments where hygiene is paramount, such as medical or laboratory settings, materials with antimicrobial properties can be particularly beneficial. These options help to reduce the risk of contamination, ensuring that the absorbent sleeve remains safe and effective in preventing spills or leaks.

Additionally, when considering material options, it is essential to evaluate factors such as thickness and texture. Thicker materials often provide greater absorbency, but may also be bulkier, potentially influencing ease of use. On the other hand, thinner materials might be more lightweight and suited for quick clean-up situations. Selecting the right material and understanding its benefits will ultimately help you make an informed choice that aligns with your absorbent sleeve needs.

This chart illustrates various absorbent sleeve materials and their corresponding benefits. The data showcases the absorbency rate and durability, which are essential factors in choosing the right absorbent sleeve for specific needs.

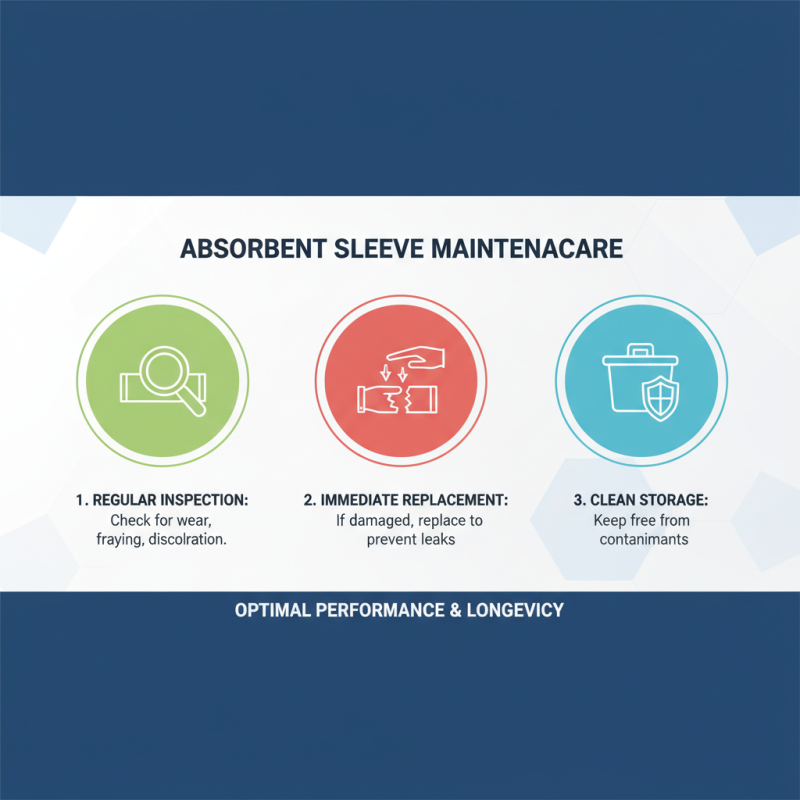

When it comes to using absorbent sleeves effectively, proper maintenance is key to ensuring their optimal performance and longevity. Regular inspection of the sleeves is essential; users should look for any signs of wear and tear, such as fraying or discoloration. If any damage is detected, it’s crucial to replace the sleeves immediately to prevent any potential leaks. Additionally, maintaining a clean storage environment helps in prolonging the life of absorbent sleeves, as contaminants can reduce their efficiency.

In terms of usage, it is important to select the right absorbent sleeve for the specific application. Different environments may require varying absorption capacities, and understanding your operational needs will guide you in making the best choice. Furthermore, following the manufacturer's guidelines on how to deploy and dispose of the sleeves will not only enhance safety but also support environmental stewardship. Proper training for personnel on the correct use of absorbent sleeves will further optimize their effectiveness and ensure compliance with safety standards.