+86 178 5514 5298

+86 178 5514 5298

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

The kPa bag is a critical innovation in packaging technology. It utilizes controlled pressure to enhance product longevity and freshness. According to industry reports, over 70% of perishable goods benefit from using kPa bags. These bags maintain internal pressure, protecting contents from external elements. This action significantly reduces spoilage rates.

However, despite their advantages, the implementation of kPa bags can be complicated. Manufacturers face challenges in ensuring consistent pressure levels during production. Fluctuations can lead to compromised product quality. There are ongoing debates regarding optimal materials for these bags. Some claim that the use of certain plastics may harm sustainability efforts.

Moreover, not all industries have adopted kPa bag technology uniformly. While food and medical sectors thrive on this innovation, others lag behind. Continuous research and development are necessary. The future growth of kPa bags hinges on overcoming current limitations. The potential benefits are substantial, and addressing these imperfections is crucial for progress.

KPa bags are specialized containers designed to maintain a specific pressure. Their main purpose varies across industries. In the food sector, these bags ensure products remain fresh. They protect from air exposure and moisture, extending shelf life significantly. Bakery items often benefit from this technology.

In the medical field, KPa bags serve a different role. They keep sterile instruments safe until use. The controlled environment prevents contamination. Additionally, these bags can store blood and tissues securely. This is crucial for hospitals and research.

While these bags are effective, there's room for improvement. Users sometimes find them difficult to dispose of properly. The environmental impact of such materials raises questions. Innovations in biodegradable options could enhance their use. Balancing functionality and sustainability remains a challenge.

KPa bags, or kilopascal bags, utilize a unique technology to maintain freshness. They create a controlled environment for food and other perishable items. The design of these bags ensures that air intake is minimized. This limits oxidation and extends the shelf life of the contents.

The science behind kPa bags involves pressure dynamics. They maintain a specific atmospheric pressure inside the bag, enhancing preservation. When air is removed, the pressure drops, creating a vacuum seal. This mechanism keeps moisture and harmful bacteria at bay. However, efficiency can vary. Not all items fare well under reduced pressure.

Tips: Use kPa bags for delicate items only when necessary. Overdoing it may compress products and alter texture. Not everything benefits from this method. Always test your items for the best results. Store kPa bags in a cool, dark place. This enhances their durability and performance.

| Dimension | Value | Description | Unit |

|---|---|---|---|

| Pressure Capacity | 20 - 200 | Range of pressure the bag can hold | kPa |

| Material Type | Polyethylene | Common material used for kPa bags | - |

| Thickness | 0.5 - 1.5 | Thickness of the bag material | mm |

| Temperature Resistance | -20 to 70 | Temperature range for safe use | °C |

| Volume | 1 - 50 | Capacity of the bag in holding contents | Liters |

kPa bags are widely used in various industries, primarily for packaging products that require protection from moisture, air, and bacteria. The key materials in their production play a crucial role in their effectiveness. One common material is polyethylene, known for its versatility and durability. It is lightweight and resistant to punctures, making it ideal for kPa bags.

Another important material is nylon, which adds strength and flexibility to the bags. It can withstand higher pressure and is often used in applications where puncture resistance is critical. Often, these materials are layered, combining their strengths to enhance bag performance. Composite structures can create a barrier that effectively keeps contents fresh and secure.

The production of kPa bags is not without challenges. Sourcing high-quality materials can be difficult. Not all suppliers meet the required standards. Additionally, manufacturing processes must be carefully monitored. Any variations can compromise bag integrity. As a result, some bags may fail prematurely. It’s essential for manufacturers to continuously evaluate their supply chain and production methods.

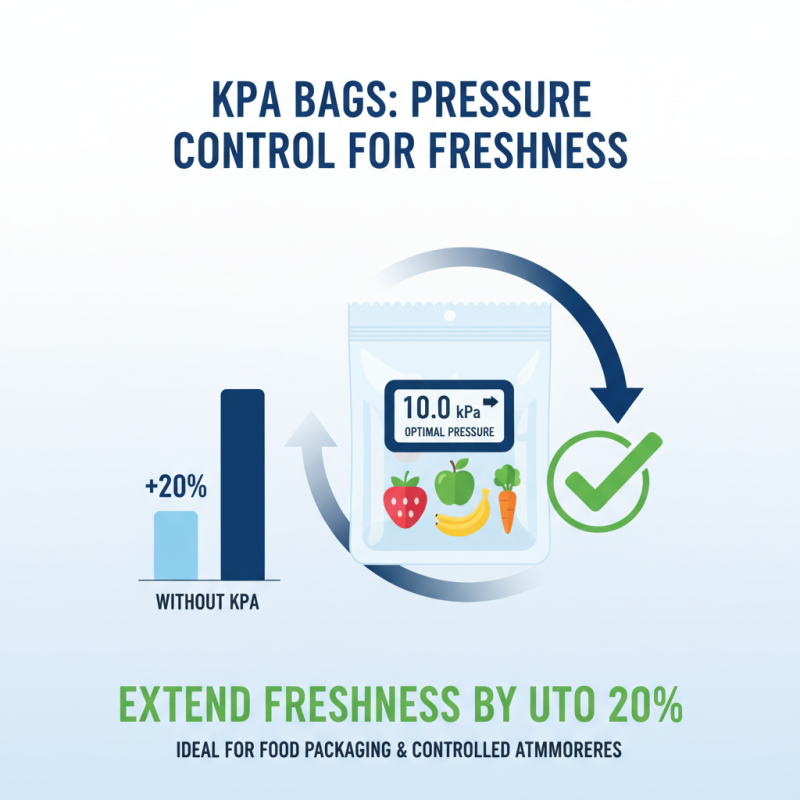

A kPa bag serves as a crucial tool for measuring and controlling pressure in various applications. These bags are often used in environments where maintaining a specific pressure is essential. For instance, during food packaging, a controlled atmosphere can prolong shelf life. According to industry reports, optimal pressure levels in kPa bags can extend freshness by up to 20%.

Understanding how kPa bags function begins with pressure measurement. They are designed to withstand specific pressure ranges, which is vital for the intended use. Utilizing barometers or pressure sensors, real-time data can be obtained. Adjustments can then be made to ensure the pressure remains stable. However, achieving this stability can be challenging. Variations in temperature and humidity often lead to fluctuating pressure levels. Such inconsistencies can compromise the integrity of the contents.

Monitoring pressure in kPa bags can sometimes be overlooked. A recent study indicated that approximately 30% of users fail to regularly check pressure levels. This lapse can result in quality degradation. Achieving the right pressure is not merely about technology; it’s about diligence and awareness of external factors. Controlling pressure requires continuous attention and adjustment.

kPa bags are innovative solutions in the packaging industry. They utilize controlled pressure to enhance product preservation. Their design aids in extending shelf life and maintaining freshness. This unique feature makes them attractive for various applications. Food products, pharmaceuticals, and electronics are some common examples.

Using kPa bags offers several benefits. They can reduce spoilage significantly. When products are secured within these bags, oxygen exposure is minimized. This can lead to reduced waste and cost savings for businesses. In pharmaceuticals, these bags protect sensitive materials from moisture. Improved stability is a direct advantage.

**Tips:** When using kPa bags, ensure proper sealing to maximize effectiveness. Monitor pressure levels regularly. Remember, bags may have limitations depending on the product's nature. Understanding these factors is essential for optimal usage.