+86 178 5514 5298

+86 178 5514 5298 Different Types of UN Approved Packaging!

1. Steel Drums (UN 1A1, 1A2)

Steel drums are among the most common types of UN-approved packaging. They are highly durable and resistant to impact, heat, and corrosion, making them ideal for liquids and solids such as chemicals, oils, or flammable materials.

- Design: Available in open-head (removable lid) or tight-head (sealed) configurations.

- Common Uses: Transporting industrial chemicals, petroleum products, or hazardous waste.

2. Plastic Drums (UN 1H1, 1H2)

Plastic drums are lightweight, cost-effective alternatives to steel. Made from high-density polyethylene (HDPE), they resist corrosion and are suitable for non-reactive substances.

- Design: Often used for liquids, powders, or granular materials.

- Common Uses: Pharmaceuticals, food-grade materials, or mild chemicals.

3. Fiberboard Boxes (UN 4G)

Fiberboard (cardboard) boxes are used for solid hazardous materials that require lightweight, disposable packaging. They’re often paired with inner liners or cushioning materials.

- Design: Must pass drop, stacking, and water-resistance tests.

- Common Uses: Batteries, dry chemicals, or medical waste.

4. Wooden Crates and Boxes (UN 4C1, 4C2)

Wooden packaging is ideal for heavy or bulky items. These crates are treated to meet international phytosanitary standards (ISPM 15) and tested for strength.

- Design: Reinforced with metal bands or cushioning for fragile items.

- Common Uses: Explosives, machinery parts, or glass containers.

5. Composite Packaging (UN 6HA1, 6HB1)

Composite packaging combines materials like plastic, glass, or metal within an outer shell (e.g., a plastic bottle inside a steel drum). This dual-layer design enhances safety for reactive or high-risk substances.

- Design: Inner receptacle + outer protective layer.

- Common Uses: Perfumes, aerosols, or laboratory chemicals.

6. Jerricans (UN 3A1, 3H1)

Jerricans are smaller, portable containers made of steel or plastic. They often feature handles for easy pouring and are leak-proof.

- Design: Typically 5–50 liters in capacity.

- Common Uses: Paints, solvents, or adhesives.

7. Flexible Packaging (UN 13H1, 13H2)

Flexible Intermediate Bulk Containers (FIBCs) or “bulk bags” are used for powders, granules, or non-liquid materials. They’re lightweight and collapsible, saving space during storage.

- Design: Woven polypropylene with liners for containment.

- Common Uses: Fertilizers, food additives, or construction materials.

8. Pressure-Receptacle Packaging (UN ISO 11623)

For gases or pressurized liquids, specialized cylinders or pressure vessels are used. These undergo extreme pressure and stress testing.

- Design: Made from steel, aluminum, or composite materials.

- Common Uses: Propane, oxygen, or fire extinguishers.

How Does UN Certification Work?

UN Approved Packaging must pass a series of tests based on the material, design, and intended contents. These include:

- Drop Tests: Simulating falls during transport.

- Stacking Tests: Ensuring structural integrity under weight.

- Leakproofness Tests: For liquids and gases.

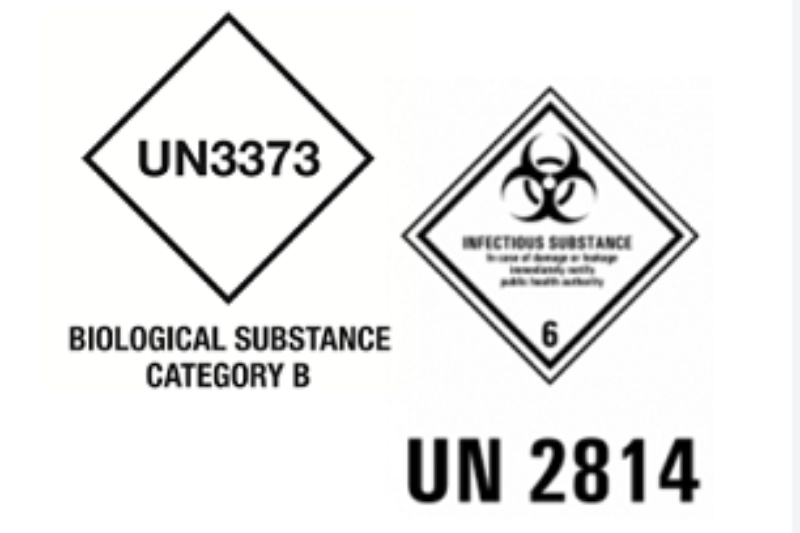

Once certified, packaging is marked with codes (e.g., UN 1A1/Y1.8/100) indicating its type, material, and maximum gross mass.

Choosing the Right UN Packaging

Selecting the correct packaging depends on:

The hazard class of the material ...e.g., flammable, corrosive.

Physical state ...liquid, solid, gas.

Transportation mode ...air, sea, road.

Always verify the UN certification mark and consult the latest IATA DGR or IMDG Code regulations.