+86 178 5514 5298

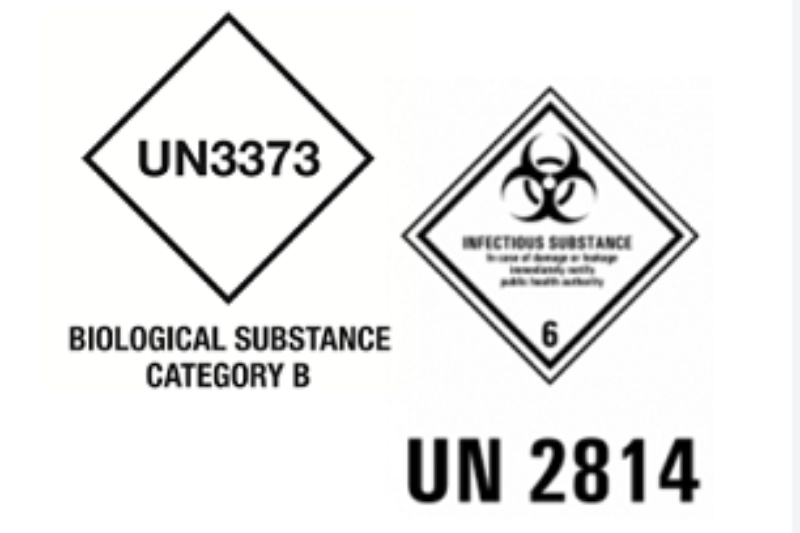

+86 178 5514 5298 How to use 95kPa bag and what can suppliers do?

The use of 95kPa bags is relatively simple, but certain steps need to be followed to ensure the safety and integrity of the samples. The following is a detailed guide to use:

I. How to use 95kPa biological sample bags

Inspection and preparation: Before use, carefully check the sample bag for damage or defects and ensure that the seal is intact. Prepare the sample tubes, bottles or other containers to be transported, and confirm that they are properly sealed and there is no risk of leakage.

Loading samples: Place sample tubes, bottles, etc. into the sample bag, taking care not to exceed the maximum capacity limit of the bag. If the sample volume is large, it can be loaded in batches, but each batch of samples must be properly protected.

Seal the bag: Pull the seal of the sample bag to the top and ensure that the seal area is clean and free of foreign matter. Press the seal hard to ensure that it is fully bonded to form an airtight closure. For bags with pre-installed absorbent pads, ensure that the absorbent pad is properly placed under the sample.

Transportation and storage: Choose the appropriate transportation method (such as road or air) according to the characteristics of the sample and transportation requirements. During transportation, avoid severe vibration or collision to prevent damage to the sample. After arriving at the destination, the samples will be sent to the laboratory or designated storage location in time and processed in accordance with relevant regulations.

2. As 95kPa bags supplier, what can we do?

As a type of large industrial building used to produce goods, the main task of a production plant is to transform raw materials into finished products to meet market demand. Specifically, a production plant can carry out the following activities:

Production and processing: Use production lines, machinery and equipment to process raw materials to make products that meet market demand.

Quality control: Establish a strict quality management system to monitor and inspect each link in the production process to ensure that product quality meets standards.

R&D and innovation: Invest funds and human resources in product research and development and technological innovation, and continuously launch new products to meet the diverse needs of the market.

Supply chain management: Establish a stable cooperative relationship with suppliers to ensure a stable supply of raw materials; at the same time, optimize inventory management and logistics processes to reduce operating costs.

Customized production: Customized production is carried out according to the specific needs of customers, providing personalized solutions.

3. What can we customize?

The production plant can provide a variety of customized services according to customer needs and market changes, including but not limited to the following aspects:

Product customization: Production and processing according to the design drawings or samples provided by the customer to make specific products that meet customer requirements. This includes customization of product appearance, size, material, function, etc.

Packaging customization: Design and produce specific packaging materials and packaging methods according to customer requirements to improve the market competitiveness and brand image of the product.

Label customization: Provide customers with label customization services, including label materials, colors, text content, etc. This helps customers better identify and manage products.

In summary, the use of 95kPa biological sample bags requires certain steps and precautions to ensure the safety and integrity of the samples. As an important place for industrial production, AIC can not only carry out large-scale production and processing activities, but also provide customized services according to customer needs to meet the diverse needs of the market.